In today’s rapidly changing energy industry, efficiency measures seldom show up in the headlines—slow, steady improvements simply don’t have much `sizzle.’ But while they may be boring, these slow, steady improvements are rewriting the rules in the utility industry.

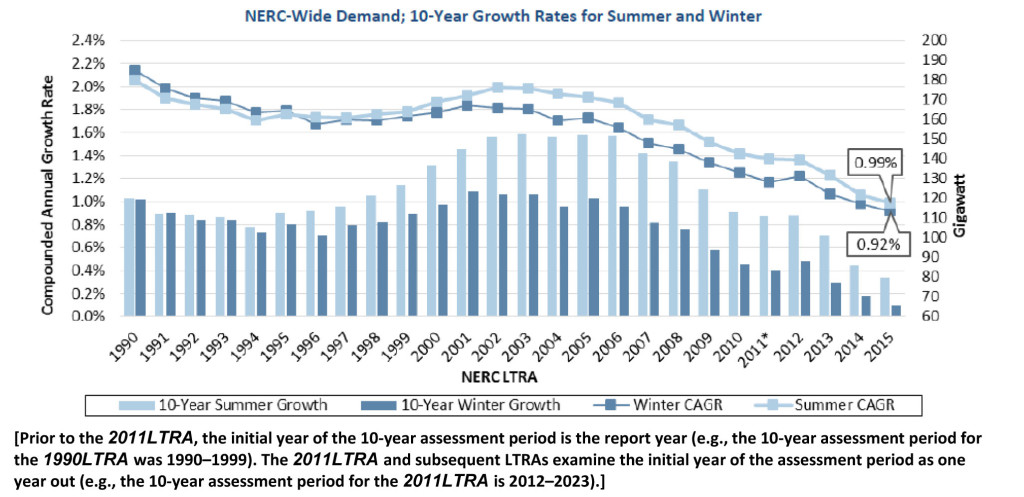

The latest indication of just how important these efficiency-related changes are occurred last month when the North American Electric Reliability Corporation released its annual long-term reliability assessment (which can be found here) of the U.S. bulk power electric system. For the first time, NERC said, its 10-year forecast for the annual growth rate in both summer and winter peak demand had dropped below 1 percent—“falling to the lowest rates on record.”

For the utility industry, where change and investment decisions are generally measured in decades, the collapse in the peak demand growth rates occurred almost overnight. Growth rates for both summer and winter peak demand bounced around essentially between 1.8-2.0 percent a year from 1990-2003 (with a couple of outlier years slightly above and below those averages), and then the slide began (see chart below). It hasn’t been precipitous, rather more slow and steady—almost as if moving in tandem with the spread of the household appliance and other efficiency measures that the Department of Energy began rolling out in the early 1990s.

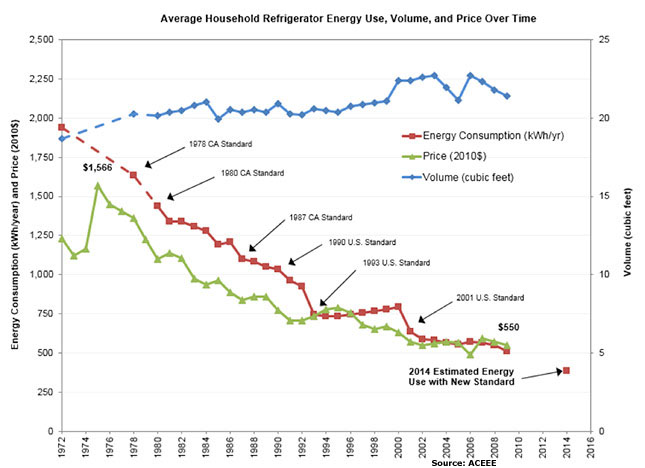

Improvements in refrigerator efficiency are perhaps the best known of these efforts. As the chart below shows, refrigerator energy use and price have come down sharply in the past 20 years, while unit size has increased—a trifecta that you can bet on. But it is by no means the only notable efficiency improvement. In fact, according to DOE, since 1990 its work to boost household appliance efficiency standards has cut energy use in:

- new washing machines by 70 percent;

- new dishwashers by 40 percent;

- new air conditioners by about 50 percent; and

- new furnaces units by about 10 percent.1

The pace of these efficiency efforts has picked up steam since the Obama administration came into office in 2009: In the past six years DOE has issued 34 new or updated standards covering more than 40 products. The department says these new efforts alone will save almost 40 quadrillion British thermal units in total by 2030—roughly equivalent to the energy currently used in all U.S. buildings in one year. Coupled with earlier standards, DOE says total cumulative energy savings could add up to more than 125 quads by 2030 (while saving consumers upward of $1.9 trillion).

Given this, it is not surprising that NERC’s report sees no end to the decline in peak demand growth. “As energy efficiency and conservation programs increase,” NERC wrote, “the declining demand growth rates are expected to continue.”

These energy savings may not be good news for utilities—figuring out how to make money in an environment where demand for your product is growing sluggishly, at best, is tough. But that is the environment utility executives must get used to—the slow, steady improvement in efficiency is destined to continue for years to come. Indeed, just two days after NERC released its 2015 assessment, DOE published two new efficiency standards covering commercial AC and furnace units that it says will be the “largest energy-saving standard in history.” Phased in, as have been most previous standards, the rule will require a 13 percent improvement in new AC and furnace units beginning in 2018, and then an additional 15 percent improvement five years later.

And other improvements are on the horizon. DOE, for example, is currently spending roughly $2 million on a research effort with GE that would wring even greater savings—upward of an additional 20 percent from today’s current standards—from the lowly household refrigerator. The research involves using the magnetocaloric effect (a process where the temperature of a material can be raised or lowered by changing the magnetic field) instead of traditional vapor compression refrigeration methods. In addition to being more efficient, the new technology would use a water-based coolant fluid, thereby avoiding the use of global warming-related fluorocarbons.

DOE estimates that the new technology could save upward of .4 quads of energy annually—hardly headline-grabbing sizzle, but a continuation of the slow, steady spread of energy efficiency improvements throughout the economy. If I were a utility executive, I wouldn’t be looking for a rise in NERC’s peak demand forecasts any time soon.

–Dennis Wamsted

¹The appliance-related statistics—efficiency improvements, and dollar and energy savings—were taken from “Saving Energy and Money With Appliance and Equipment Standards,” published by DOE’s Building Technologies Office. It is available here. (Web page accessed January 6, 2016)

Follow

Follow